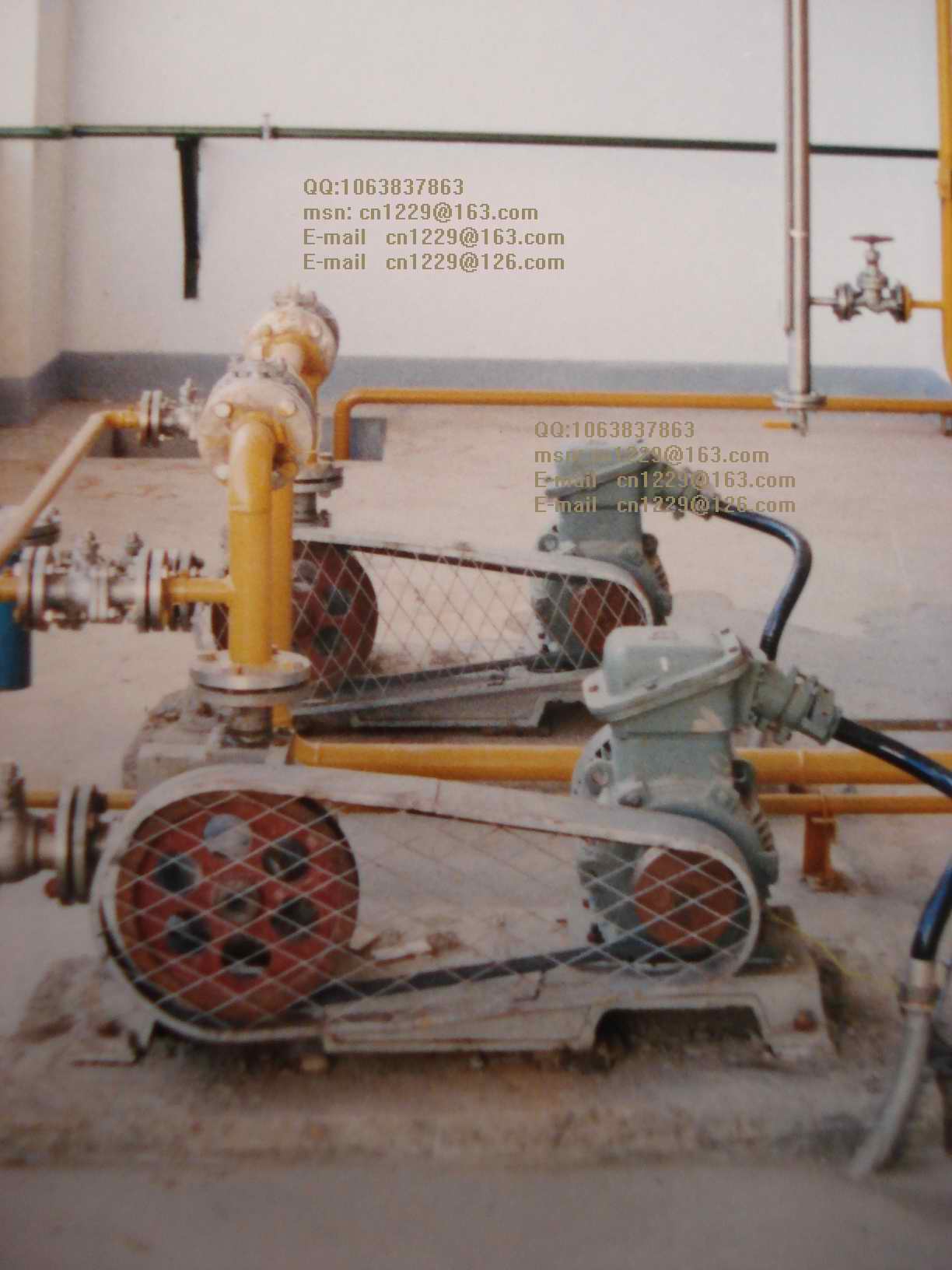

制氢纯化设备

液氨加热至800~850℃,在镍基催化剂作用下,将氨进行分解,可以得到含75%H2、25%N2的氢氮混合气体:

本装置工艺流程,有液氨瓶送来的氨经过进氨阀F1,F2进入汽化器(1),汽化器内装有电加热元件,电加热元件对汽化器内的水加热,一般水温控制在45-60℃,液氨在汽化器内得到温水传过来的热量。汽化成气态氨,一般汽化后的氨压力控制在0.4-0.5MPa,氨气经减压阀减压后,压力调到0.05 MPa左右。经过降压后的氨气由耐腐流量计量,从流量计流出的氨气在热交换器中进行热量交换,使氨气温度升高,由分解炉出来的高温混合气被降温,经升温后的氨气进入分解炉进行分解成氢氮混合气,高温混合气进入热交换器,水冷却器降温,然后送到使用地点。

复式流程,用两只吸附干燥器并联,一只工作,同时另一只可以进行再生处理。相互交替工作和再生,以保证设备连续运行。干燥器在常温下工作,在加温至350℃下冲气再生。再生废气经阀F17后,通过气水分离器放空。

Hydrogen purification equipment

Liquid ammonia was heated to 800 ~ 850 ℃, in the nickel-based catalyst, the decomposition of ammonia, hydrogen and nitrogen can be a mixed gas containing 75% H2,25% N2 of:

This means the process has brought a bottle of liquid ammonia through the ammonia into the ammonia valve F1, F2 to enter the carburetor (1), carburetor built with electric heating elements, electric heating elements for heating water in the carburetor, the general temperature control in 45-60 ℃, liquid ammonia to obtain warm water over the heat transfer in the evaporator. Vaporized into gaseous ammonia, ammonia vaporized pressure is generally controlled 0.4-0.5MPa, after ammonia gas after decompression valve, pressure at about 0.05 MPa. After the ammonia down by decay after dosing flow meter from flowing ammonia gas in a heat exchanger in heat exchange, so that the ammonia temperature by decomposing furnace out of the high-temperature gas mixture is cooled, warmed by decomposition of ammonia into the furnace is

|